Automotive Supply Chain Management

A resilient supply chain you can rely on

Smaller margin for error

Just-in-time manufacturing helps control variability, productivity, and costs. However, there are downsides. Companies experience sudden surges in demand and, due to the precision of the system, are more susceptible to supply chain shocks. Shortages of materials or parts will delay shipments. With time-sensitive orders, OEM organisations face profitability risks and customer dissatisfaction.

Supply chain complexity

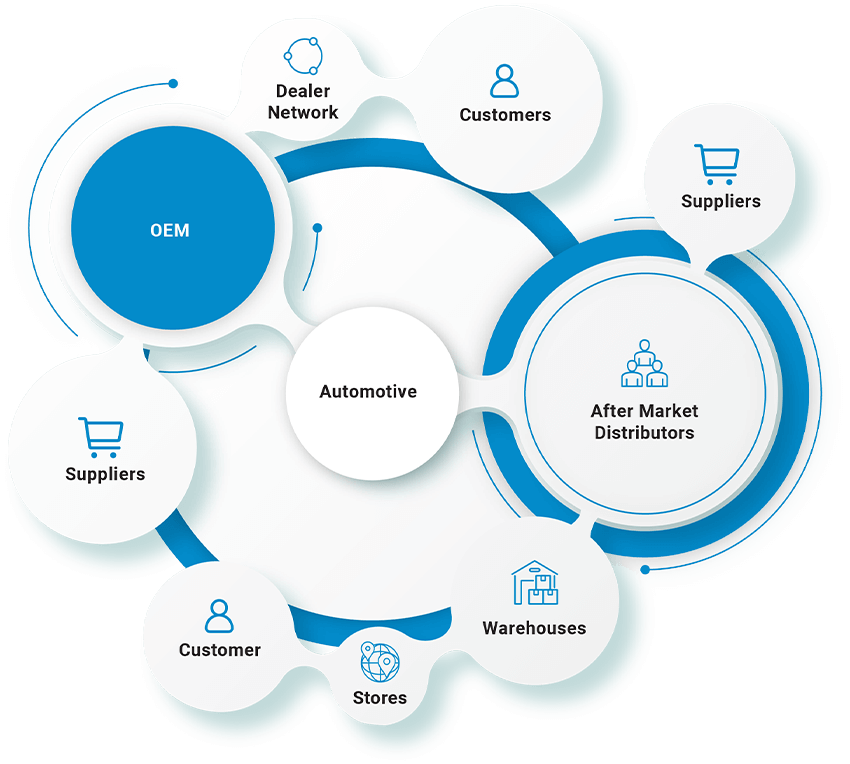

The average OEM vehicle contains around 30,000 separate parts manufactured in house or sourced from third-parties. Automotive supply chain managers must work with thousands of manufacturers and suppliers. Delays in the supply chain slows the manufacture and distribution of critical components, which could lead to shut downs to production which are very costly based on the just in time (JIT) model the OEM market uses.

Supply network disruption

The last few years have highlighted the need for automotive supply chains to be disruption-proof. For example, the global computer chip shortage reduced one leading manufacturer’s output by 40% in 2021 and, in 2020, the Covid-19 pandemic caused a 16% decline in worldwide production. Supply chains must be resilient to endure problems like these.

Unique document set

OEM automotive supply chains also use a very specific set of electronic documents to ensure that the just in time supply chain operates efficiently. Many documents such as the material release schedule (MRS) aren’t easily integrated into systems and in fact a supplier or manufacturer will only use this for planning. This means smaller and specialist suppliers, as well as suppliers in other regions can’t easily adopt integrated EDI solutions.

After market complexity

The after market supply chain is similarly complex. Thousands of different brands and models are on the roads. To maintain these, thousands of suppliers for original and after market parts must in-turn be delivered to thousands of garages, usually with very short delivery times, to keep cars serviced and running as the diversity of parts mean garages tend not to keep a lot of stock. Similarly there's a large industry of after market automotive retailers who need to connect to thousands of suppliers to stock fast moving consumable products as well as greater automotive aftermarket range.

Solutions for the automotive industry

EDI

Web EDI

Web Portal

Helping your automotive supply chain thrive

Increased accuracy and visibility

Using B2BE’s EDI and Web Portal solutions, OEM automakers and after market distributors can expect greater data accuracy through their supply chain. Viewing partners on one platform enables greater transparency with changes updated in real time, allowing responsiveness and customer service usually reserved for more online and consumer-facing organisations.

Automation reducing costs

Traditionally, automotive supply chain improvements were left until production was complete. However, moving away from manual data entry is an immediate necessity, one that will speed up automotive supply chains and minimise errors. These benefits will reduce operational costs while increasing productivity and better allow the management of the changing automotive supply chain.

Any document any way

OEM automotive particularly means a very specific set of documents that need to be traded, which may follow UNEDIFACT or ANSI X12 standards, depending on where the manufacturer or their systems reside. B2BE’s flexible approach means suppliers in the automotive supply chain can integrate part or all of the documents and maintain compliance and responsiveness.

On-boarding and engagement

While OEM automotive is particularly advanced with EDI solutions, after market automotive distributors still face a slower up-tick with supplier electronic engagement. The B2BE solutions help automate, but B2BE also manages the on-boarding process to remove the day to day of supplier engagement.

Automotive supply chain connections